Additive Manufacturing (AMA-3D Printers) Lab

Location: IGRM 4204

Scope:

The Additive Manufacturing (AMA) lab facilitates research and active learning in Additive Manufacturing, specifically on the Fused Deposition Modeling (FDM) process. AMA also supports the work of undergraduate students in the Senior Design Course. AMA promotes students’ limitless creativity. Additive Manufacturing entails the design a three-dimensional object with computer-aided design software, the determination of part specifications and features and the use of a 3D printing machine that extrudes a filament (usually plastic) and applies one layer of this material at a time.

Research:

Students have solved problems such as:

- Optimizing the quality of 3D printed parts

- Optimizing the time to produce 3D printed parts

The solution of these problems entails the use of engineering materials, statistics, engineering design graphics, design of experiments and optimization courses

Works have been presented in national and international conferences such as:

- Annual International Solid Freeform Fabrication Symposium (SFF)

- Gulf Coast Undergraduate Research Symposium (GCURS)

Course Work:

Students in the Senior Design course have printed prototypes of products or parts that have enhanced a diverse range of operations at manufacturing and service companies such as printing replacement parts for robots and products for industrial applications such as aerospace and quality control.

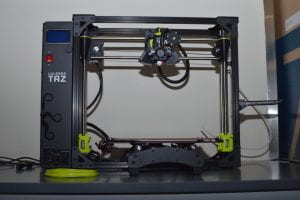

Hardware:

- 3D printing equipment

- 1 Makerbot 5th generation replicator 3D printer

- 1 Makerbot Z18

- 1 Makerbot 3D Digitizer

- 1 LulzBot Taz 6 3D Printer

Software:

Students can develop their projects in their personal laptops or desktops equipped with the software listed below and ask for help of Dr. Novoa or a graduate student working under her supervision to print their projects

-

- Makerbot Print (needed if printing in the Makerbot 5th generation replicator or Makerbot Z18)

- CURA Lulzbot software (needed if printing in the LultzBot 3D Printer)

- Office Enterprise (includes Microsoft Visio and Microsoft Project) Needed for any notes and presentations related to your work

- Thingverse (optional if looking for ideas or to learn more about 3D printing)

- Mathematica (optional if wanting to print figures generated as solids of revolution, etc.)

- AutoCAD (optional; the software may be useful to design of the objects to print )

- Solidworks (optional; the software may be useful to design the objects to print)

Faculty:

- Clara Novoa, Professor at the Ingram School of Engineering Industrial Engineering Program. Her main research areas are Operations Research (OR), the use of High-Performance Computing for solving large-scale OR problems. She has also developed research interests in Additive Manufacturing and its interplay with OR (i.e., Mathematical Optimization and Statistics).

Students Involved:

- Industrial Engineering Undergraduate Students:

- Jacob Cheramie (Spring’19 – Spring’ 20)

- Alejandra Flores (Spring’18 – August’18)

- Javier Ortiz (Spring’ 17 – Spring’18)

Publications (students involved are bolded):

Conference Proceedings:

- Novoa, C., Flores, A (UGST). (2019) Optimizing the Tensile Strength for 3D Printed PLA Parts. Proceedings of the Annual International Solid Freeform Fabrication Symposium (pp. 745-765)

Posters:

- Flores, A. (UGST), Novoa Ramirez, C. M., The 29th Annual International Solid Freeform Fabrication Symposium, “Active Learning for Engineering Students at the WIND Lab 3D Printing – Optimizing the Tensile Strength for 3D Printed PLA Parts,” Austin, TX, United States. (August 14, 2018).

- Ortiz, J. (UGST), Novoa Ramirez, C. M., Fifth Women in Science and Engineering (WiSE) Conference, “Active Learning for Engineering Students at the WIND Lab 3D Printing Initiative,” Texas State University. (April 28, 2017).